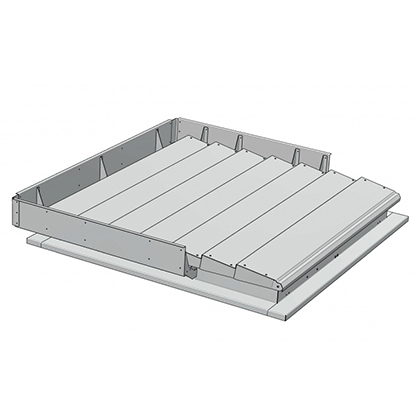

mcr LAM louvered vents are part of natural smoke exhaust system, with principal purpose of removing hot fire gases outside building. Louvered vents produced by MERCOR are available in wide range of dimensions, types of control system and making options. mcr LAM louvered vents are conformant with the normative PN-EN 12101-2.

Types of mcr LAM louvered vents

| TYPE | MIN | MAX |

| mcr LAM | 800 x 500 [mm] | 3800 x 2500 [mm] |

Technical description of standard

Functions

Control systems

Additional equipment