Key details

fire damper for comfort ventilation

Fire resistance class: EI120(ve ho i↔o)S

Dampers certified for conformance with EN 15650.

Additional details

Certificate of constancy of performance 1488-CPR-0203/W and 1396-CPR-0114.

Dampers are classified as per EN 13501-3 and tested according to EN 1366-2.

Declaration of performance 006-05-CPR-2015.

Optional EX making of dampers (as per ATEX directive) for applications in explosion hazard zones.

KDB ATEX 17.0616, EU Declaration of conformity 001-01-2017.

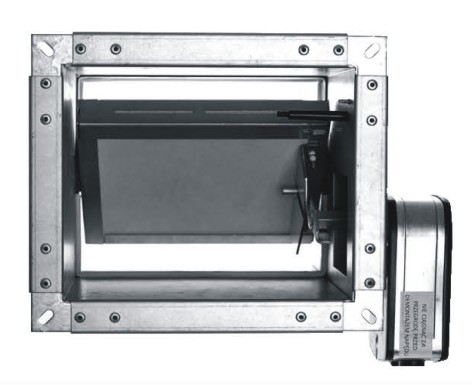

Description

mcr FID S/S c/P low-resistance cut-off dampers are designed for use in general ventilation installations, in points of penetration of these installations through vertical and horizontal building partitions. The dampers are used, among others, for installations with increased acoustic requirements. During fire, they allow to maintain fire resistance of the building partition through which ventilation and air conditioning ducts run. They also prevent propagation of fire, smoke and fire gases to the safe part of the building.

Cut-off dampers of fire resistance independent from direction of air flow and of installation side.

Reduced acoustic noise and hydraulic resistance in the system due to reduction in thickness of the barrier.

When made for potentially explosive zones (EX variant), the dampers may operate in zone 1 (risk of explosion of gases inside and outside of ventilation ducts) and zone 21 (risk of explosion of dust outside ducts). The dampers conform to the requirements of group II category 2G and -/2D.

Dimensions:

Apart from standard dimensions, dampers can be customized to any size within the specified ranges.

Control:

The use of MP230/24 element enables the powering/triggering of KW1 mechanism with 230V AC voltage.

Detailed technical data are contained in the technical catalogue.

Making variants:

Additional equipment:

This site uses the cookies to ensure better user experience and functionality. Using our site you agree to using cookies. Cookies can be allowed or blocked, or adjusted. Check it.

(+48) 58 341 42 45

ul. Grzegorza z Sanoka 2

80-408 Gdańsk

Mercor © 2024 All rights reserved.

Projekt i wykonanie:Wiselimber Interactive